Metal ring seals can be used to protect a variety of equipment, from the most delicate machinery to the toughest industrial settings. But choosing the wrong seal can mean costly repairs and downtime. In order to maximize efficiency and longevity, it is essential to choose durable metal seals that can withstand the toughest conditions. In this article, we will discuss the different types of metal seals available, their advantages and disadvantages, and how to choose the right seal for your needs. We'll also discuss how to maintain and care for metal seals and how to extend their lifespan. With the right information and selection of metal rings and seals, you can ensure maximum efficiency and prolonged performance.

Understanding the role of metal ring seals in maximizing efficiency

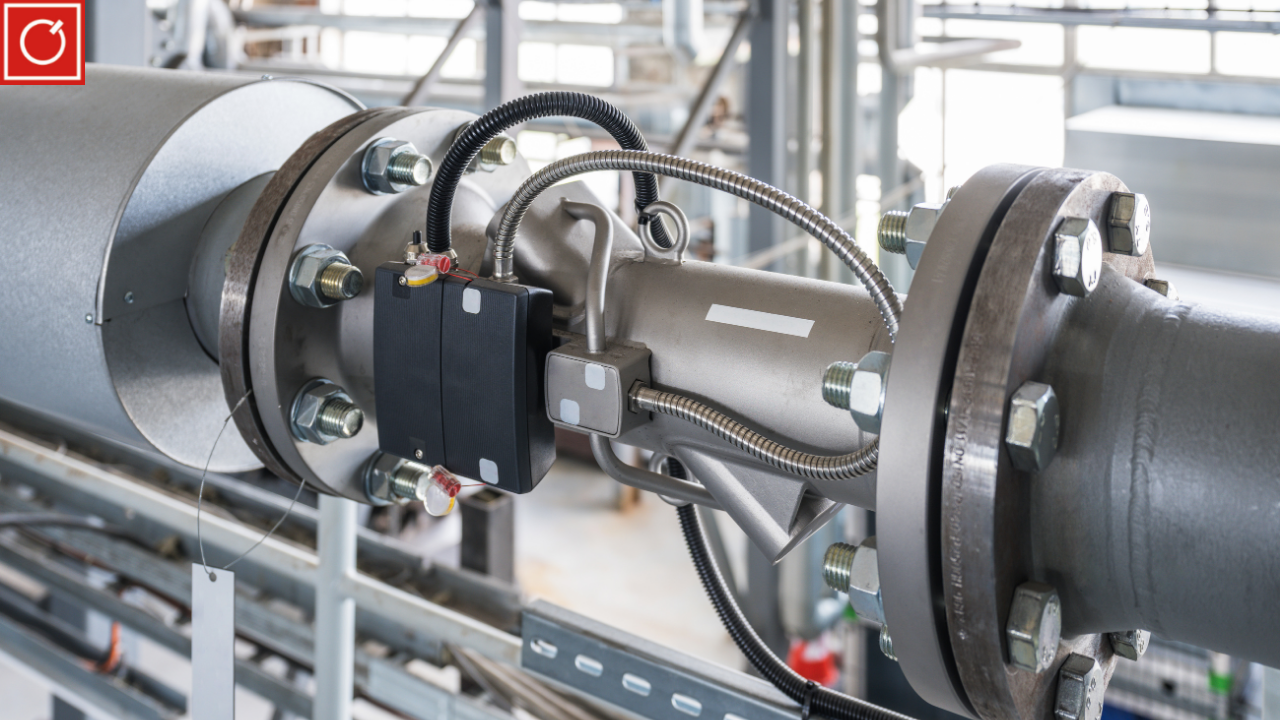

Metal ring seals play a critical role in maximizing efficiency and longevity in any production environment. They are durable, reliable, and able to handle the toughest conditions. Metal rings are used for a variety of purposes, including maintaining pressure and providing a leak-free seal between two objects. They are often used in the automotive and aerospace industries, where their effectiveness and durability are key factors in maximizing the lifespan of components.

Metal ring seals are designed to be tough and are able to withstand extreme temperatures, chemicals, and high pressures. By stopping the leakage of fluids, they can make production more efficient and reduce downtime. In addition, they can also be used to reduce the risk of contamination from outside sources. With the right seal, it's possible to maintain a consistent level of efficiency over extended periods of time.

Metal ring seals are also highly customizable, allowing for a wide range of applications. They come in various sizes, materials, and shapes, making them suitable for any environment. Metal ring seals are also easy to install and maintain, making them ideal for production line operations. With the right seal, you can ensure that your production line runs efficiently and without interruption.

Durability of metal ring seals in various industrial settings

Metal ring seals are a reliable and durable option for industrial applications, offering superior performance and longevity compared to other types of seals. They provide excellent sealing capabilities and can withstand harsh conditions and temperatures.

Metal ring seals can be used in a range of industrial applications, including automotive, aerospace, and oil&gas. They offer superior protection from environmental factors and are extremely durable, making them perfect for long-term seals for both small and large applications.

When it comes to maximizing efficiency and longevity, metal ring seals are a great option. They offer superior leak prevention and resistance to wear and tear, ensuring a secure seal that will last over time. Furthermore, they are also less prone to corrosion and are more resistant to extreme temperatures. This makes them ideal for industrial applications where long-term sealing is required.

In conclusion, metal ring seals offer excellent protection and durability in industrial settings. They are easy to install and provide superior sealing capabilities, making them the perfect choice for long-term sealing. With their excellent corrosion resistance and temperature tolerance, metal ring seals are a reliable and durable option for a variety of industrial applications.

Factors that contribute to the longevity of metal ring seals

Metal ring seals provide superior sealing performance and exceptional longevity. Here are some of the factors that contribute to the durability of metal seals:

1. Durable Materials: Metal seals are often made out of durable materials, such as stainless steel or Nickel alloys, which can withstand harsh environmental conditions, such as extreme temperatures, high pressure and corrosive chemicals.

2. High-Quality Manufacturing: Metal seals are designed to meet rigorous standards, which ensures they are made to precise specifications and have superior durability.

3. Superior Strength: Metal seals are designed to have superior strength and can withstand pressure, shock and vibration.

4. Corrosion Resistance: Metal seals are designed to be corrosion-resistant and are able to withstand exposure to moisture, humidity, saltwater and other corrosive agents.

5. Low Maintenance: Metal seals require little maintenance and can be used in many different applications without having to worry about wear and tear.

These factors all contribute to the superior longevity of metal ring seals. By using high-quality materials and precise manufacturing processes, metal seals can provide superior sealing performance and long-lasting durability.

Proper maintenance and inspection of metal ring seals

Having metal ring seals on your machinery is a great way to ensure efficiency and longevity. Proper maintenance and inspection of these seals is the key to maximizing the life of your equipment. Here are some tips to help you get the most out of your metal ring seals:

1. Lubricate seals regularly. Make sure to use the right type and amount of lubricant. This will help to reduce wear and tear, and keep the seals working properly.

2. Inspect seals for signs of damage or wear. Look for cracks, chips, or other irregularities. If you detect any damage, replace the seal immediately.

3. Clean metal seal surfaces. Cleaning the surfaces of the seal can help keep it in good working order. Use a soft brush or cloth to clean the surface, and avoid using abrasive cleaning products.

4. Use the right tools for installation and removal. Using the wrong tools can damage the seals, reducing their effectiveness and longevity. Make sure to use the tools recommended by the manufacturer.

Following these tips can help you get the most out of your metal ring seals. Regular maintenance and inspection will help ensure that your seals stay in good condition, and will help maximize the life of your equipment.

Conclusion and recommendations

In conclusion, metal ring seals and metal sealing rings offer superior performance in terms of efficiency and longevity. Their durability and resilience make them ideal for a variety of applications, allowing them to last longer and provide better performance than many other types of seals. With the right care, these seals can provide years of reliable service and will help you maintain a productive and efficient operation.

Sonkit Industry Technology Co., Ltd. is a privately-owned company that was founded in 2010. Starting in 2012, Sonkit specializes in metallic seals. We develop and manufacture high-performance metal seal rings. In 2018, we customized a series of high-end heat-treating equipment to solve heat treatment quality control problems.

Our plant is located in Shanghai, China. We can research and develop, customize, and manufacture metal seal products for critical environments that are subject to extremes of temperature, pressure, medium, or combinations of these factors. The applications of our products include flow meters, defense and military, nuclear, mold, chemical fiber, semiconductor and vacuum pumps, aircraft engines, and pressure pipelines, among others.

Sonkit provides the following products:

Our benefits include:

• Experienced research and technical support team

• Stable and reliable electroplating process

• Customized heating process with high reliability

• In-house test labs for high-quality control

• Quick response time

• Close cooperation with renowned universities and research institutes

• Experience collaborating with top 500 enterprises worldwide

Feel free to reach out to johnny@sonkit.cn(sales) for product and solution inquiries. WhatsApp: +86 13917192435. Website: www.sonkit.cn/en.