How to install Metal Seal properly to achieve target sealing effect? instructions by Sonkit

Classification:Company Updates Release date: 2022-02-23 12:50

In order to achieve target sealing effect, installation is also very important. In this acticle, Sonkit recommend some instructions so that you can follow and deploy metal seal properly.

Installation Instructions

In order to get better sealing effect, kindly recommend customer to follow this installation instruction. Before that, we should know that to achieve the ideal sealing effect, the factors as follows are very important:

• Reasonable selection of surface coating

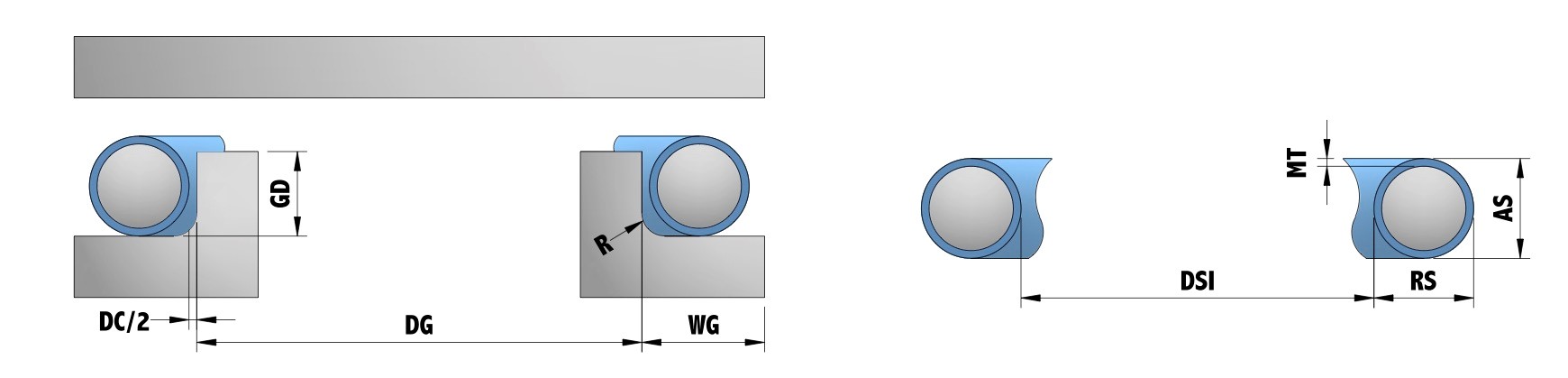

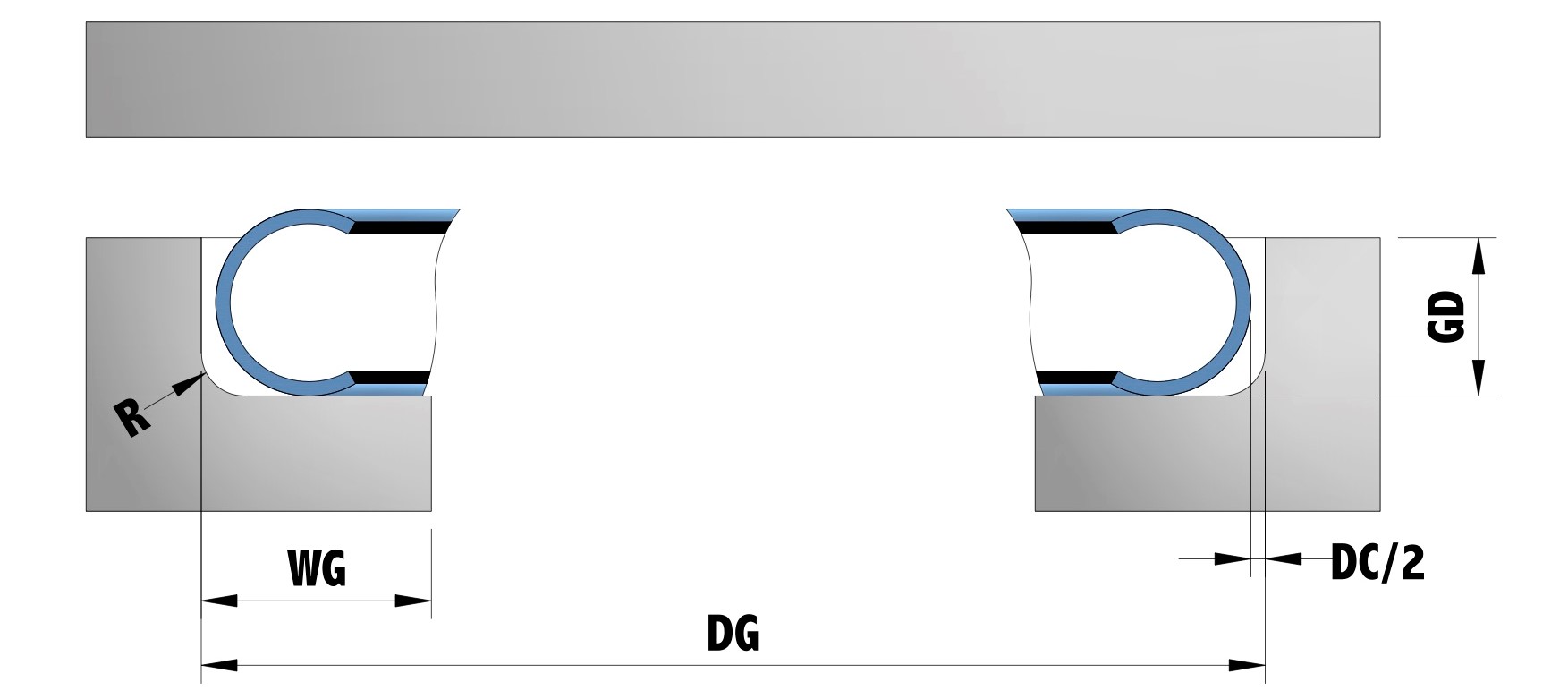

• Appropriate groove size

• Appropriate flange roughness

• Working conditions within the design conditions

• Sufficient bolt load

1. Sealing Ring

* To prevent damage to the seal ring, make sure that the original package of the seal ring is not damaged before installation

* When opening the package, prevent sharp objects from scratching the sealing ring, even if the surface of the sealing ring is slightly scratched, it may lead to the risk of leakage

* When installing the metal seal ring, sonkit recommends that you carefully check the groove for possible problems, such as scratches, damage, etc

* When placing or checking the sealing ring, sonkit recommends that you wear clean gloves to install

2. Groove or Flange

* Sonkit requires that the circumferential direction of the installation groove or flange must be consistent with the processing direction, and the directly milled groove or flange surface may cause leakage.

* The smaller the load, the higher the smoothness of the sealing surface

* The leakage rate mainly depends on the sealing condition and the surface roughness of the groove

* The type of sealing ring directly determines the roughness of sealing surface

* Make sure that the mounting groove, flange or cover plate is free of dust, oil, or burrs

* Very small scratches can cause leakage unless the direction of the very small scratches is consistent with the circumferential direction of the groove

* Before installation, sonkit recommends using a clean cotton cloth dipped in a little isopropanol or acetone to wipe the groove, flange or cover plate. And check the groove for scratch, damage or other possible conditions

3. Installation

* The sealing ring must be put into the groove very carefully to prevent scratches

* The cover plate or flange must be placed on the placed sealing ring carefully to prevent the sealing ring from being damaged or scratched

* Try to avoid using lubricating oil, grease or other auxiliary installation materials to contact with the sonkit metal seal ring

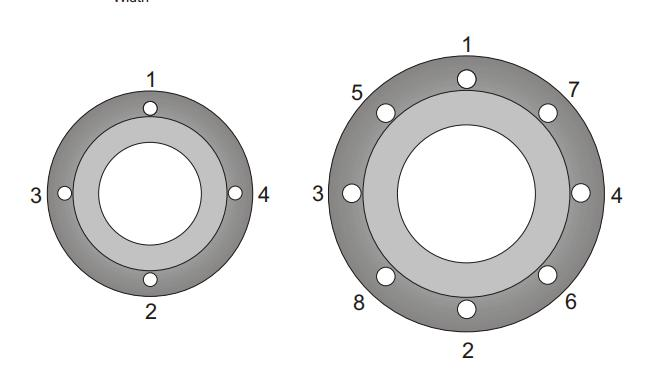

* If it is tightened with bolts, please use the cross method to install the nuts and tighten the nuts one by one (20% - 50% - 80% - 90% - 100%) to ensure that our sealing ring is compressed smoothly

---------------------------

For more information about Metal Seal or inqueries, Please contact johnny@sonkit.cn

Sonkit Industry